As discussions around the housing crisis intensify, governments at every level aresearching for creative and…

Choose Your Glass Fabricator Wisely

Areas to Consider Before Picking Your Next Equipment Fabricator

Your grandmother always told you that you get what you pay for, but is that always true? When it comes to choosing a vendor for manufacturing glass handling equipment, grandma was right. Making a wrong choice could lead to some very, very expensive mistakes.

Fabricator Capabilities

When it comes to fabricating steel for glass handling equipment, it’s not a job that can be done by just any standard welding company. The first thing to consider is whether or not the metal fabricator vendor you’re considering has experience with your type of project. Fabricators tend to specialize into different industries. If you’re looking for glass handling and assembly equipment fabrication, you won’t want to choose an auto parts fabricator! All fabricating processes have different requirements, so you’ll need to ensure the vendor you choose can handle the type, grade, and gauge of metal required for your project.

Experience

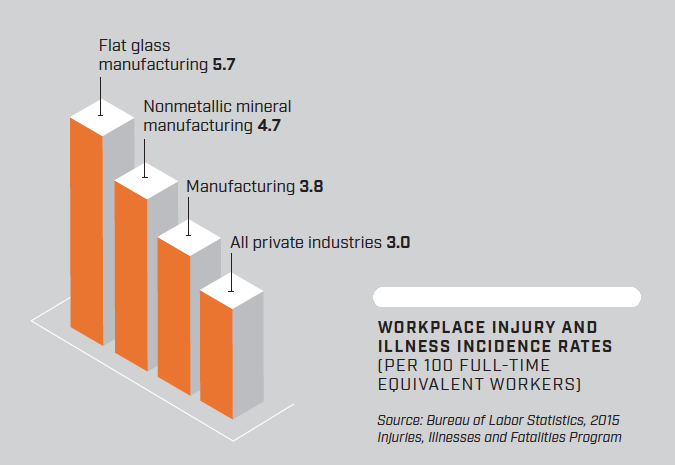

Like most aspects of life, experience matters! This point is even more important when considering that the safety of your employees is at stake. According to the Bureau of Labor Statistics, the glass manufacturing industry reports higher-than-average incidence rates for workplace injuries and fatalities. In 2015, the flat glass manufacturing segment reported an incidence rate of 5.7 injuries or illnesses per 100 full-time workers, according to the BLS. This is higher than the total injury and illness rate of 3.0 for all private industries, 3.8 for all manufacturing and 4.7 for all non-metallic mineral manufacturing, of which glass manufacturing is a part.

Many glass plant injuries are the result of crush injuries rather than glass cuts. It’s imperative that you look for experienced vendors who understand the ins and outs necessary to engineer equipment specifically made for the glass industry. Taking an inexperienced fabricator a drawing will not get you a duplicate of a high quality piece. The last thing you want is to purchase a poorly designed glass rack that breaks and crushes an employee.

Industry Credentials

Ask what certifications the metal fabrication company holds. Are they members of the most respected organizations, like the Window and Door Dealer Alliance (WDDA), National Glass Association (NGA) or the Window and Door Manufacturers Association (WDMA)? Being part of glass manufacturing associations is important because it shows their commitment to the industry and an understanding of the unique challenges at hand to safely build glass handling equipment.

Customer Service

When choosing your glass handling equipment fabricator, look for a company who understands the fenestration industry, who focuses on craftsmanship, and who values good old-fashioned customer service. Ask to speak to customers directly and don’t be afraid to go with your gut!

About Wakefield Equipment

Wakefield Equipment specializes in the fenestration industry and Wakefield’s experts have searched for the most innovative and reliable equipment for fabricating, handling and processing glass. Wakefield’s experts also offer support to our fenestration customers. From our specialized equipment and products, to our unmatched service to help you reduce labor, handling and waste, while increasing your productivity and profits.