In fenestration manufacturing, the hum of saws, drills, and air compressors is a constant. But…

Why Use an Edge Deletion Table when Manufacturing Insulated Glass?

Image Source: GlazCon

Edge Deletion of Insulated Glass Units

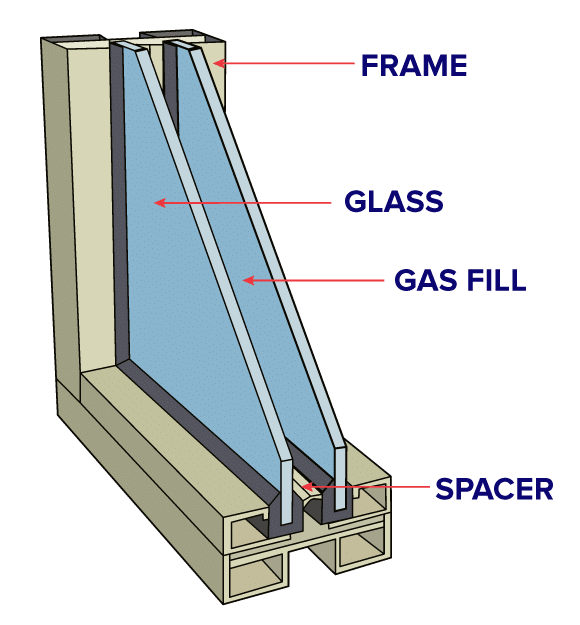

Insulated glass (IG) units are manufactured from two or more layers of glass that are separated by a spacer and then sealed using sealants. In order for the sealants to adhere to the glass, any moisture-sensitive coatings need to be fully removed, or edge-deleted. Edge deletion is the removal of a narrow strip of coating around the perimeter of a sheet of glass that has been cut to size so that the sealants can bond directly to the glass.

Removing the edge of low-e glass is an essential part of making IG units. It can take a considerable amount of skill and effort when done by hand. When edge deletion is done with manual grinding equipment, it can be difficult to ensure that the deletion is both complete and consistent. Additionally, many low-e coatings contain layers of reactive metals that can affect the sealant bond over time if exposed to moisture or chemicals.

Signs of incomplete edge deletion are easy to see visually, although they are not always caught. A very simple way to check for proper edge deletion is to place a piece of clear glass of the same thickness as the coated glass next to the edge deleted area. Place a piece of white paper through the deleted area and the clear glass. If you have proper edge deletion, the white paper will appear about the same shade of color through the deleted area as it is through the clear glass.

Fortunately for window manufacturers, there are a variety of cost effective machines available to achieve edge deletion and eliminate costly edge deletion failures. Wakefield Equipment offers both a single edge deletion table and a twin edge deletion table designed to increase both productivity and operator safety at the same time.

Wakefield’s twin edge deletion tables feature:

- Effortless transferring of glass on and off the table

- Non marking, carpeted top which allows air to blow through to create a cushion of air

- Two sides can be cut simultaneously, increasing productivity

- Vacuum blower holds glass in place, freeing up operators’ hands

All of Wakefield’s products are designed to help you increase employee productivity, reduce overall costs, and ultimately make a better window. Contact Wakefield Equipment to learn more about how we can customize an edge deletion table to suit your production needs.